In the modern office environment, equipment failures can disrupt workflow and incur costly repairs. Predictive maintenance offers a solution by using technology to forecast potential issues before they occur. This blog explores how businesses can implement a predictive maintenance strategy, save up to 35% on repairs, and extend the lifespan of office equipment. From monitoring performance to creating a maintenance checklist, learn how to optimize office operations with predictive maintenance and increase overall productivity.

In today’s fast-paced work environment, we rely on office equipment more than ever. The last thing anyone wants is to face unexpected equipment failures. Not only do these disruptions cost valuable time, but the repairs can be expensive too. But what if I told you that you could save up to 35% on office equipment repairs by using a predictive maintenance strategy?

In this blog, I’ll break down what predictive maintenance is, how it works, and how it can be a game-changer for your business. If you’re looking for a way to stay ahead of costly repairs and improve office productivity, this post is for you.

What is Predictive Maintenance?

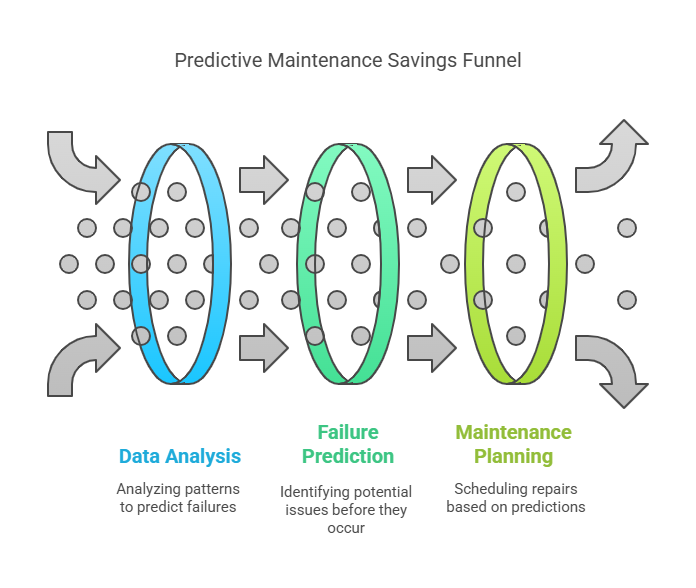

Predictive maintenance is a strategy that uses data and technology to predict when equipment will fail so that maintenance can be performed just in time to address the issue. Instead of waiting for a problem to occur, predictive maintenance focuses on identifying potential issues before they cause downtime.

By utilizing sensors and monitoring systems, you can analyze the health of your office equipment, track its performance, and schedule maintenance in advance. This helps avoid the need for costly repairs and prolongs the lifespan of your machines.

- Minimizes Unplanned Downtime: Predictive maintenance allows you to address issues before they cause unexpected breakdowns.

- Improves Equipment Reliability: With predictive maintenance, you can ensure that your equipment performs at its best for longer.

- Prolongs Equipment Lifespan: Regular monitoring and timely fixes can significantly extend the life of your office equipment.

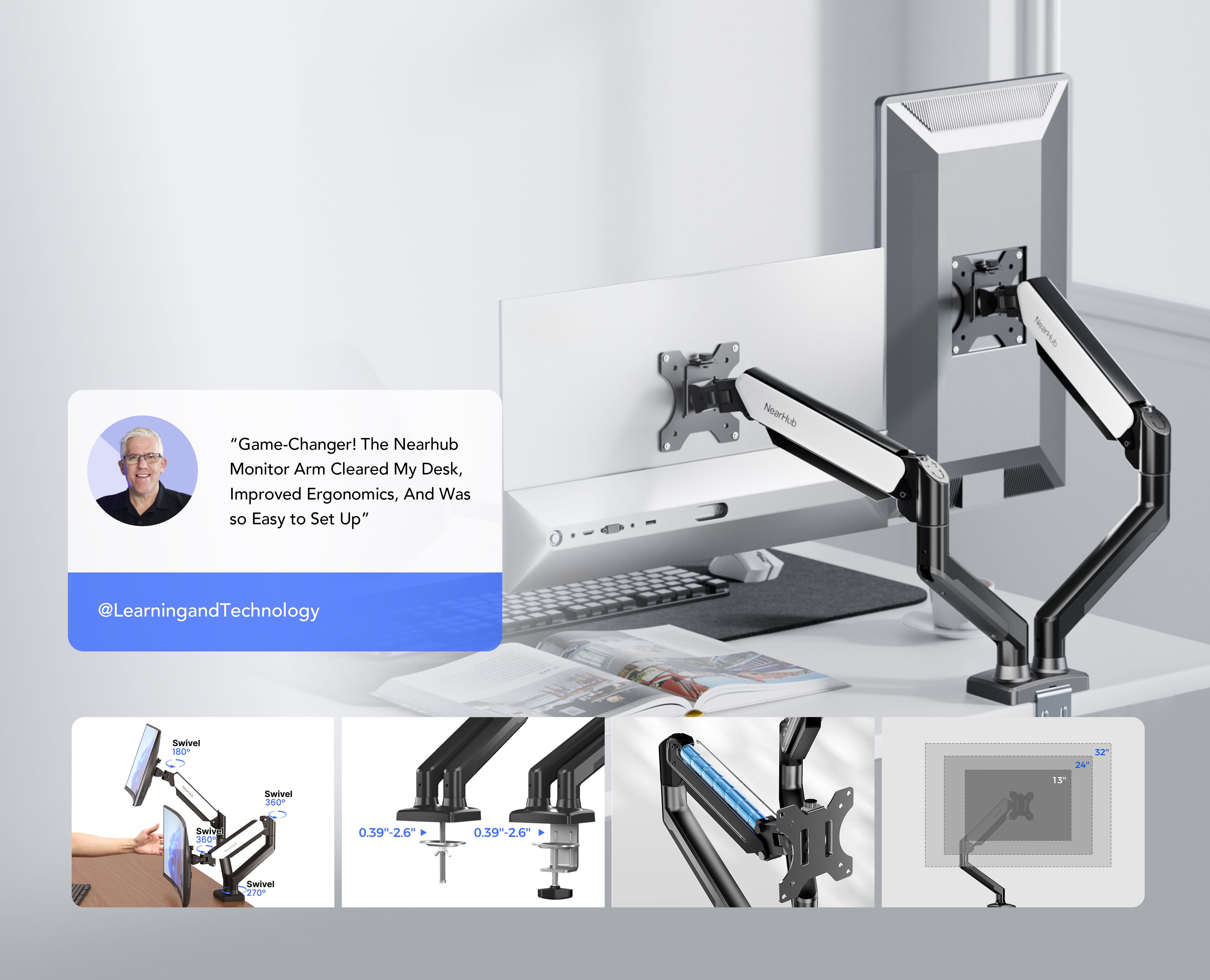

For example, let’s say you use a high-end printer in your office that constantly jams. With office equipment maintenance, you can set up a system that monitors the printer’s performance, detects any irregularities, and alerts you when it’s time for maintenance—before the problem escalates. The same principle applies to other office devices. If you use a dual 32 monitor mount for multiple displays, predictive maintenance can help you ensure that the mounting system remains secure and reliable, preventing issues like loose mounts or poor display alignment that could disrupt your workflow.

How Predictive Maintenance Strategy Saves Costs

The benefits of predictive maintenance strategy go beyond just preventing unexpected downtime. One of the most significant advantages is the cost savings. Here’s how:

- Reduced Repair Costs: Regular maintenance before a failure occurs means less need for expensive emergency repairs.

- Longer Equipment Lifespan: Proactive care increases the longevity of your office equipment.

- Minimized Downtime: By addressing issues before they become critical, you can avoid disruptions to your team’s workflow.

- More Accurate Budgeting: With predictable maintenance costs, you can plan your budget more effectively.

- Less Waste: Timely maintenance ensures that you don’t need to prematurely replace equipment that could have been repaired.

By implementing a predictive maintenance strategy across your office equipment, you'll see fewer breakdowns, better resource utilization, and higher overall productivity.

How to Implement an Office Equipment Maintenance Plan

Creating an office equipment maintenance checklist is a great place to start. Here’s how you can put a plan into place:

- Identify Critical Equipment: List all the equipment that’s essential to your business—computers, printers, copiers, and other devices.

- Monitor Performance: Use sensors and tracking tools to keep an eye on the performance of your machines.

- Schedule Regular Check-ups: Set up a routine to check the condition of your office equipment.

- Train Your Team: Educate your team on best practices for maintaining equipment and the importance of regular checks.

- Prioritize Based on Usage: Regularly check high-usage equipment (like printers, copiers, and computers) more frequently than less-used equipment.

- Track Maintenance History: Keep records of when each piece of equipment was serviced, so you can anticipate future needs.

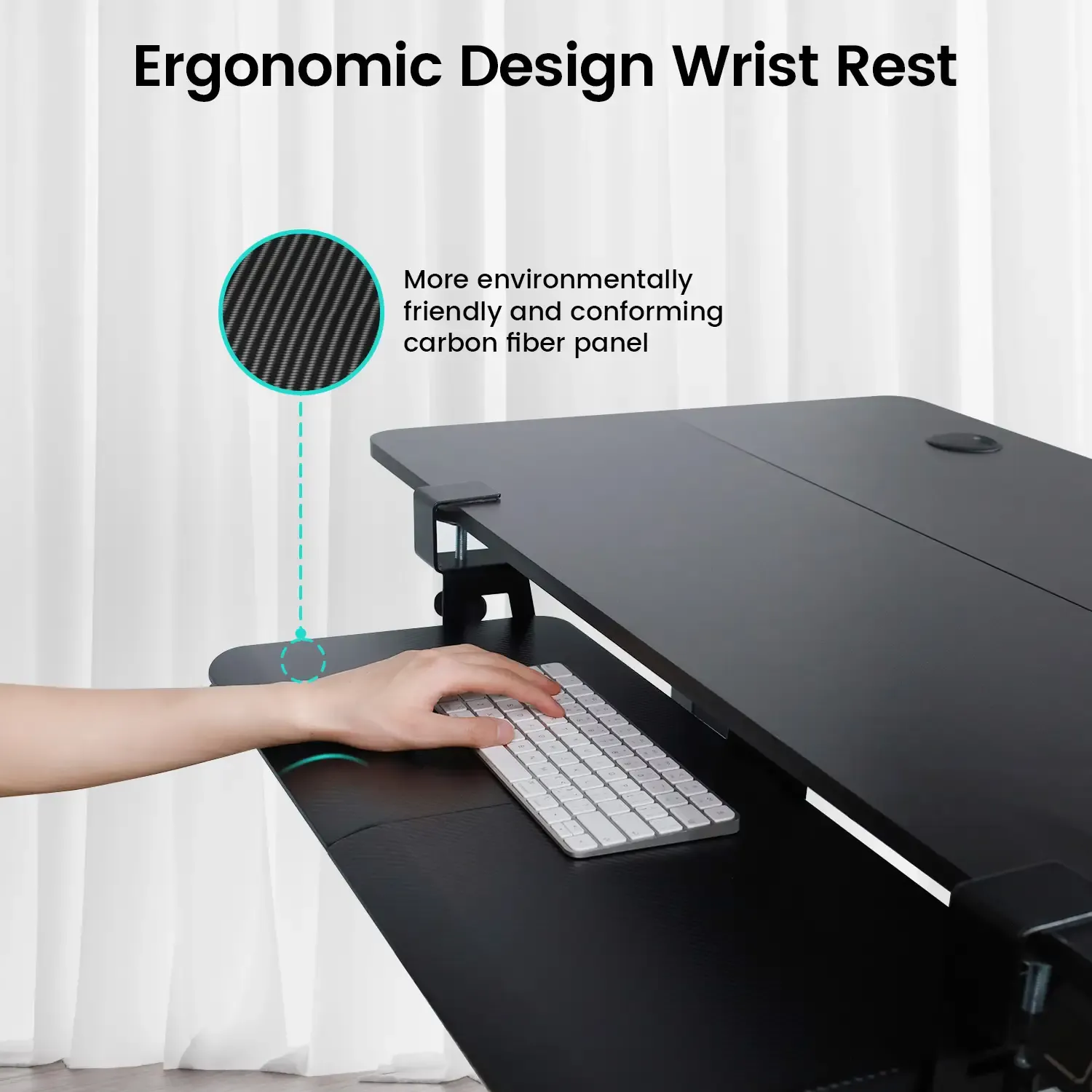

By following an office equipment maintenance checklist, you’ll ensure that all equipment is regularly monitored and properly maintained. Don’t forget, it’s important to ensure comfort for your entire team, including those who may need specialized seating. For tall individuals, a comfortable office chair can make a world of difference. Consider the ergonomic desk chairs for big and tall to provide the necessary support and comfort for longer working hours.

Key Benefits of Predictive Maintenance for Your Office Equipment

Now, let’s dive into the benefits of adopting predictive maintenance for your office equipment:

- Improved Efficiency: You’ll avoid the frustration of equipment failures disrupting your workday.

- Cost Savings: With fewer repairs and replacements, you’ll save a significant amount of money in the long run.

- Better Decision Making: With real-time data, you’ll be able to make more informed decisions about when and how to replace or repair your office equipment.

- Increased Equipment Lifespan: Regular monitoring and timely maintenance will extend the life of your equipment, saving you the cost of early replacements.

- Enhanced Workplace Productivity: When equipment works efficiently, employees can focus on their tasks, reducing downtime and boosting productivity.

- Reduced Risk of Accidents: By fixing potential equipment malfunctions early, you lower the risk of accidents caused by faulty machinery.

For a more comfortable office setup, consider ergonomic options like an ergonomic chair for short people, which can improve posture during those long work hours. Or if your team includes taller individuals, investing in an ergonomic desk chair for big and tall can provide more comfort and support, preventing unnecessary strain.

Why Predictive Maintenance is the Future of Office Equipment Maintenance

Predictive maintenance is more than just a buzzword—it’s a forward-thinking solution that can save businesses a significant amount of money. By adopting this strategy, you can prevent equipment failures, reduce repair costs, and improve overall productivity in your office.

It’s the smarter way to maintain your office equipment, and it’s becoming a key part of modern workplace operations.

If you’re someone who spends long hours at a desk, make sure your setup is optimized for comfort. An undermount keyboard tray can help improve posture and keep your workspace organized. And if you’re working with dual monitors, a dual monitor arm for 13-32 displays can significantly reduce neck strain while increasing productivity.

FAQs About Predictive Maintenance for Office Equipment

Q: What is predictive maintenance?

A: Predictive maintenance is a maintenance strategy that uses real-time data and technology to predict when equipment is likely to fail, allowing you to perform maintenance just in time to avoid costly repairs.

Q: How can predictive maintenance save me money?

A: By identifying and fixing potential issues before they cause failure, predictive maintenance reduces the need for expensive emergency repairs, improves the lifespan of equipment, and reduces downtime, which translates to significant cost savings.

Q: What equipment benefits most from predictive maintenance?

A: Predictive maintenance is especially effective for equipment that’s crucial to your daily operations, such as printers, copiers, computers, and other high-value office machinery.

Q: Can I create an office equipment maintenance checklist?

A: Absolutely! A good office equipment maintenance checklist should include monitoring equipment performance, scheduling routine checks, and addressing any issues before they escalate.

Q: How often should I maintain office equipment?

A: The frequency of maintenance depends on the type of equipment and its usage. However, with predictive maintenance, you can monitor equipment in real time and maintain it as needed, reducing unnecessary maintenance while preventing breakdowns.

By implementing predictive maintenance and adhering to an office equipment maintenance checklist, you’ll not only reduce the need for costly repairs but also ensure your office equipment runs efficiently. If you haven’t already, consider incorporating this strategy into your office operations—it’s the future of smart and cost-effective maintenance!